Designing a Technological structure for an industrial facility is a critical task that goes beyond conventional framing. These structures form the core support system for advanced process equipment, dense piping networks, cable trays, heavy equipment and cooling units, ensuring seamless plant operations. This blog outlines the design philosophy, major challenges, and engineering strategies adopted to deliver a high-performance technological steel structure that meets the demands of modern industry.

Project Overview

Structure Type:

A technological industrial steel structure designed to support:

-

High-density piping networks for process and utility systems.

-

Critical technological equipment such as air coolers, vessels, pumps, heat exchangers, and control panels.

-

Access platforms for operation and maintenance.

Design Scope

-

Modeling:

A detailed 3D model created in STAADPro replicating geometry, stiffness, and connectivity. -

Loading:

Load cases including dead loads, live loads, pipe/equipment operating loads, hydro-test conditions, thermal effects, wind forces, and seismic actions. -

Analysis:

Structural stability checks, dynamic analysis for seismic effects, and vibration control for sensitive equipment. -

Structural Drawings:

Complete GA drawings, member schedules, and connection details for fabrication and erection. -

Foundations:

Isolated pedestal foundations with anchor bolts designed for combined tension and shear, ensuring stability under uplift and overturning.

Primary Challenges

The primary challenge was to develop a safe, efficient, and structurally sound steel framework capable of supporting advanced technological equipment and a dense network of piping. The design needed to address multiple critical factors simultaneously, including seismic wind resistance, serviceability requirements, and accommodation of thermal movements. This combination of performance, safety, and adaptability formed the cornerstone of the engineering approach for the project.

Design Challenges

Complex Load Interactions

-

Dynamic forces from rotating equipment affect vibration performance.

Seismic and Wind Effects

-

High-level platforms and coolers create large lateral forces.

-

Avoiding torsional irregularities due to asymmetric equipment layout.

Thermal Movements

-

Managing expansion forces from long pipe runs without overstressing supports.

Foundation Uplift

-

Braced frames inducing tension under wind and seismic loads.

Constructability

-

Modularization for faster erection and future maintenance access.

Engineering Strategy and Structural Design

Advanced Modelling and Analysis

-

Comprehensive 3D model was developed in STAAD.Pro, accurately representing geometry, member releases, and load paths.

-

Key analysis steps included Static and dynamic load cases, Response Spectrum Analysis, and Frequency checks.

Structural System Selection

-

The framework was designed as braced frames for lateral stability under wind and seismic forces.

-

Moment resisting connections in critical bays for stiffness.

-

Secondary beams and stringers for equipment platforms and walkways.

Connection Detailing

-

Design connections to ensure efficient force transfer between structural members under all load combinations.

-

Incorporate practical and standardized details that simplify fabrication, enable quick erection, and allow easy inspection.

BIM Integration

The structural model was integrated into a BIM environment to:

-

Coordinate with piping, equipment, and electrical layouts.

-

Detect and resolve clashes early in the design phase.

-

Facilitate accurate fabrication drawings and material take-offs.

Safety and Access

-

Walkways, stairs, and ladders designed for ergonomic access and compliance with industrial safety standards.

-

Guardrails, toe plates, and anti-slip grating for personnel protection.

-

Clear maintenance routes and lifting paths for equipment removal and servicing.

-

Fire safety provisions are integrated with structural layout.

Load Management and Serviceability

Serviceability checks ensured:

-

Story drift limits for pipe alignment.

-

Deflection control for equipment supports.

-

Vibration performance within acceptable limits for sensitive machinery.

Foundation Design

-

Foundations were designed to resist combined vertical, lateral, and uplift forces from wind and seismic actions.

-

Anchor bolts and base plates were detailed for tension and shear, ensuring stability under extreme load cases.

-

Adequate embedment depth and edge clearances were maintained to prevent concrete failure.

-

Soil capacity, settlement, and sliding resistance were verified to ensure long-term performance.

Design Outcome Summary

-

The structural system provided robust lateral stability with efficient bracing and optimized load paths.

-

Thermal movement allowances were successfully integrated, preventing overstress in piping and equipment connections.

-

Connection detailing and anchorage design ensured reliable performance under cyclical and reversible loads.

-

BIM integration improved coordination, eliminating clashes and streamlining fabrication and erection workflows.

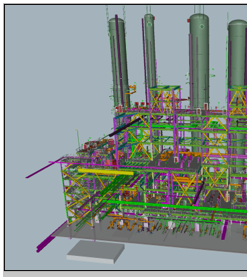

Snaps of the prepared 3D model and the wireframe view generated in STAAD for analysis

Conclusion

Designing a technological structure for an industrial facility demands a holistic approach that combines advanced analysis, precise detailing, and practical constructability. The final design not only meets structural safety and serviceability requirements but also ensures material efficiency, future adaptability, and ease of maintenance. Through BIM integration, optimized connections, and well-planned access provisions, the structure stands as a reliable and sustainable solution for modern industrial operations.

About Author

The author Shana Iqbal is an experienced structural engineer having 6+ years of experience in structural design, analyzing, and managing diverse structural projects. Skilled in applying engineering principles to ensure safety, functionality, and cost-effectiveness. She has worked on apartments, refinery and power plant structures, with a strong focus on innovative and sustainable design solutions. With expertise in structural analysis software, construction practices, and project coordination, she brings both technical knowledge and practical insight to every project.