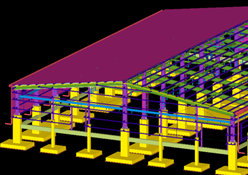

We take pride in delivering engineering solutions that push the boundaries of conventional design. One of our most technically ambitious and rewarding undertakings involved the design and analysis of a multi-level warehouse, incorporating crane systems and all modeled and validated using advanced 3D tools.

This wasn’t just a theoretical exercise, it was a real-world design challenge, executed with precision by coordinating with MEP, and aimed at maximizing usable space without compromising structural integrity.

Project Overview

• Structure Type: Multi-level warehouse with integrated storage and logistics zones

• Design Scope:

-

Superstructure:

-

Steel or RCC frame system based on span and load requirements

-

Roof trusses or portal frames for large clear spans

-

-

Foundations:

-

Deep foundations (bored piles or raft) based on soil conditions

-

Pile caps and grade beams to distribute loads from columns and crane supports

-

-

Crane System Integration

-

Overhead Gantry Cranes:

-

Design runway beams and brackets for EOT (Electric Overhead Travelling) cranes

-

Include crane columns and bracing for lateral stability

-

-

Monorail or Jib Cranes:

-

Localized support systems for workstation-level lifting

-

-

• Primary Challenge: Design a warehouse with cranes and other lifting mediums for storage of different hazardous substances.

Key Design Challenges

• Managing high live loads from forklifts and storage racks

• Foundation design complexity due to heavy point loads from crane columns and differential settlement risk because of uneven loading from cranes

• Navigating variable soil strata and groundwater conditions

• MEP Routing conflicts like overhead space constraints, service accessibility etc.

Engineering Strategy & Structural Design

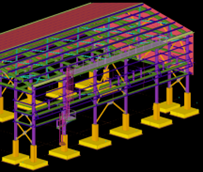

To meet the design goals, we adopted a top-down structural approach, supported by detailed 3D modelling.

Core Design Elements:

• Crane Load accommodation by using high-strength steel beams and precast concrete girders

• Design for dynamic loads, including impact, acceleration, braking, and lateral sway

• Foundations are considered as isolated or pile foundations

• Early-stage BIM Integration: Use Building Information Modelling (BIM) from the conceptual stage to coordinate crane supports, structural elements, and MEP systems

• Dedicated Crane Pathways: Reserve overhead zones exclusively for crane runways and lifting operations, with MEP routed around or beneath these paths

3D Modelling & BIM Integration

• The entire structure was modeled using Building Information Modelling (BIM) tools

• Clash detection and tolerance checks were performed to ensure constructability

• Underground MEP utilities are integrated into the BIM model, and clash detection is performed to ensure coordination with structural elements and avoid interference during construction

Design Outcome Summary

• A structurally sound warehouse was designed with integrated crane systems for storage and services

• Crane-supporting beams and columns were optimized for dynamic loads, deflection control, and vibration resistance

• Crane-supporting beams and columns were optimized for dynamic loads, deflection control, and vibration resistance

• Structural elements were validated for seismic, wind, and operational loads using advanced analysis tools

• The design complies with IS, BS EN, and OSHA standards, ensuring safety, durability, and operational efficiency

Conclusion

This warehouse design demonstrates the integration of structural innovation and operational efficiency. Using detailed analysis, 3D modeling, and adaptive engineering, we developed a high-performance facility that meets modern industrial needs while ensuring safety and functionality.

About Author

The author Ashly Paul is an experienced structural engineer having 6+ years of experience in structural design, analyzing, and managing diverse structural projects. Skilled in applying engineering principles to ensure safety, functionality, and cost-effectiveness. She has worked on refinery and power plant structures, with a strong focus on innovative and sustainable design solutions. With expertise in structural analysis software, construction practices, and project coordination, she brings both technical knowledge and practical insight to every project.