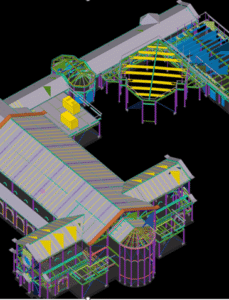

At Paradigm, we take pride in delivering engineering solutions that challenge conventional boundaries. One of our most technically demanding and rewarding projects involved the structural steel detailing of a church building in the US. This was not a theoretical case study or academic concept—it was a real project, executed under live conditions. Here’s how we did it.

Project Overview

-

Building type: Church Building

-

Scope: Steel detailing work for the entire church building

-

Primary challenge: A church with beautiful architectural features

Key Challenges

-

Complex connections

-

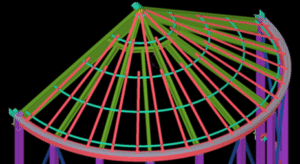

Dome area modelling

Our Solution: Engineering Strategy

-

Discussion with customer regarding solutions for complex connections, especially on curved areas

-

Precise modelling of architectural elements

Key methods included:

-

Architectural drawing study: Architectural drawings were studied and executed in such a way that all the requirements of the owner meet the building design.

-

Expertise detailing team: A special team was formed to work on this job with a high level of experience.

Execution Highlights

Our execution is up to the drawings delivery stage.

Engineering Tools & Coordination

Tekla used as 3D-modelling software for this job.

✅ Project Results Summary

Project executed with high quality within scheduled time.

Conclusion

This project stands as a testament to our ability for detailing complex structures which have high architectural features.

About the Author

Dias Jose is an experienced Detailing Engineer with 15+ years of experience in steel detailing and delivering complex structures for commercial, industrial, and infrastructure projects. Skilled in project coordination, checking, and customer relationships.