Introduction

Circular platforms are an integral part of refinery structures. They are used to support heavy equipment, pipelines, and access systems, while also ensuring safety and stability for operational needs. Preparing accurate designs and detailed drawings for such platforms requires a blend of engineering expertise and advanced modelling tools.

Project Overview

In our company, we have successfully executed many refinery projects involving circular platforms and their foundations. Each project required close coordination with process, piping, and mechanical departments to meet the complex functional requirements.

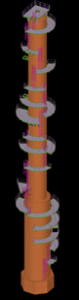

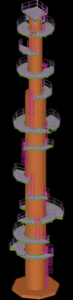

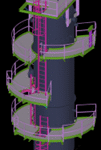

Snaps from Model and drawings

Structural Analysis and Design

The process begins with a thorough structural analysis. Circular platforms often need to carry eccentric loads from pipelines, vessels, and rotating equipment. Our engineering team carefully evaluates:

-

Load combinations (dead, live, equipment, wind, seismic, piping, snow, etc.).

-

Foundation interaction, considering soil conditions.

-

Dynamic effects, especially where rotating machinery is involved.

We ensure that the design complies with industry standards and project-specific guidelines. The outcome is a safe, efficient structure capable of long-term performance.

Foundations are critical for refinery platforms, especially since they support concentrated loads. Our detailing covers:

-

Raft and isolated footing design.

-

Anchor bolt layouts and embedment details.

-

Reinforcement schedules for concrete works.

-

Special detailing for vibration and heavy equipment loads.

Modelling and Detailing

Once the design is finalized, we will be converting concepts into highly detailed 3D models.

-

Model primary and secondary steel members with precision.

-

Generate detailed connections suitable for fabrication.

-

Prepare general drawings showing anchor bolts, pedestals, and reinforcements.

-

Create clash-free models by coordinating with piping and equipment layouts.

The 3D model ensures better visualization, quick revisions, and high-quality deliverables for both fabrication and erection.

Deliverables & Results

Upon completion, the following engineering outputs are generated:

-

Analysis and Design results

-

3D Model

-

2D general arrangement drawings

-

Erection and fabrication drawings

-

Design calculation report

Conclusion

Over the years, we have successfully completed many refinery projects involving circular platforms. Each project presented unique challenges, from congested layouts to strict safety requirements. Our combination of structural analysis, design expertise, and Tekla modelling has helped us deliver accurate, constructible, and cost-effective solutions.

By integrating advanced analysis with Tekla modelling, we provide end-to-end solutions that ensure structural safety, fabrication accuracy, and ease of construction on-site.

About Author

Rinshadul Haque K P is a Structural Engineer specializing in design, Tekla modelling, and structural drawing preparation. With hands-on involvement in various industrial projects, including power plants and refineries, the author brings a practical understanding of BIM-based workflows and detailing standards. Passionate about precision and coordination, they focus on delivering efficient, high-quality structural solutions using modern tools and technologies.

Related Services

Explore More Of Our Expertise: