Designing infrastructure for power generation facilities demands precision, resilience, and adaptability, especially when the site is exposed to seismic activity and high wind forces. One of our recent projects involved the design and structural detailing of a multi-level electrical substation building, tailored to house critical electrical equipment, battery rooms, cable trenches, and utility spaces like toilets with sunken slabs. This blog outlines the engineering strategy, challenges, and solutions behind this technically demanding structure.

Project Overview

• Structure Type: Multi-level RCC-framed electrical substation building

• Design Scope:

• Accommodate high-voltage electrical equipment, control panels, battery rooms, and cable trenches across multiple floors

• Include toilets with sunken slabs, ventilation shafts, and fire-rated enclosures

• Ensure seismic resistance, wind stability, and service accessibility

• Foundation System:

• Isolated and combined footings designed based on geotechnical and seismic zone data

• Integration of cable trenches and underground utilities within the foundation layout

• Waterproofing and anti-corrosion protection for below-grade components

Primary Challenge

The primary challenge was to design a structurally resilient building that could safely support heavy electrical equipment and allow for extensive floor cutouts, sunken slabs and cable trenches—while maintaining integrity under seismic forces and high wind pressures.

Design Challenges

• Seismic Load Management: Designing for lateral forces, base shear, and drift control in a multi-level structure

• Wind Load Resistance: Ensuring stability against uplift and lateral wind pressures, especially on exposed facades

• Floor Cutouts for Equipment: Required precise structural detailing to maintain slab integrity and load paths

• Battery Room Isolation: Needed chemical-resistant flooring, ventilation, and structural separation

• Sunken Slabs in Toilets: Demanded accurate slope design, waterproofing, and plumbing integration

• Cable Trench Coordination: Trenches had to be structurally integrated without affecting foundation performance

• MEP Clash Avoidance: Underground utilities and electrical conduits required careful routing and BIM-based clash detection

• Fire Safety Compliance: Required fire-rated walls, emergency exits, and smoke extraction systems

Engineering Strategy & Structural Design

Structural Framing

• RCC frame with slab-beam-column system designed for high equipment loads, seismic forces and wind pressures

• Floor cutouts modeled in BIM to ensure zero clashes and reinforcement continuity

• Sunken slabs detailed with step-down geometry and integrated waterproofing membranes

Seismic & Wind Design

• Seismic analysis performed

• Wind load calculations done with bracing and shear walls are checked for lateral stability

• Drift limits and ductility factors considered in structural detailing

Foundation Design

• Isolated and combined footings sized for concentrated loads and seismic base shear

• Cable trench walls tied into foundation beams for structural continuity

• Soil-structure interaction considered for differential settlement control

BIM Integration

• Full 3D modeling of structure

• Clash detection performed to resolve conflicts between cable routes, plumbing, and structural members

• Construction sequencing and maintenance zones visualized for execution planning

Safety & Compliance

• Design aligned with Standard Codes

• Battery rooms designed with ventilation shafts and chemical containment zones

• Emergency access and fire-rated enclosures included in layout planning

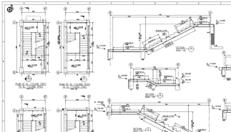

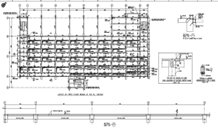

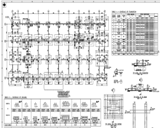

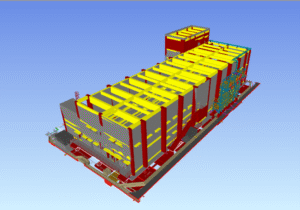

Snaps of the prepared structural drawings

Design Outcome Summary

• A multi-level substation building was successfully designed with full integration of structural and MEP systems.

• Floor cutouts and sunken slabs were incorporated without compromising structural performance.

• Seismic and wind loads were addressed through advanced analysis and detailing.

• Cable trenches and underground utilities were coordinated using BIM, ensuring zero clashes.

• The structure meets all operational, safety and regulatory requirements for power infrastructure.

• The final design supports efficient equipment layout, service access and long-term durability.

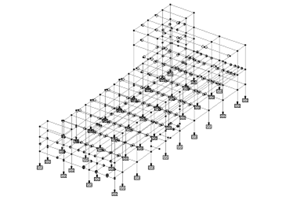

Snaps of the prepared 3D model and the wireframe obtained in STAAD for analysis

Conclusion

This project exemplifies our ability to deliver resilient and technically sound infrastructure for power generation facilities in challenging environments. Through advanced structural analysis, BIM coordination, and adaptive engineering, we created a substation building that meets modern industrial demands safely, reliably, and sustainably.

About Author

The author Athul Shaji is an experienced structural engineer having experience in structural design, analyzing, and managing diverse structural projects. Skilled in applying engineering principles to ensure safety, functionality, and cost-effectiveness. He has worked on refinery and power plant structures. With expertise in structural analysis software, construction practices, and project coordination, He brings both technical knowledge and practical insight to all projects.