Project Overview

This project involved the comprehensive structural design and detailing of a Conveyor System for a chemical production facility. The system comprised:

-

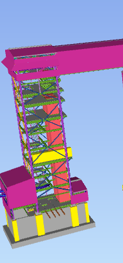

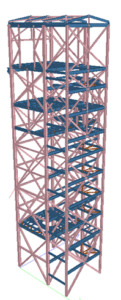

Transfer Towers: 60-meter-high vertical structures housing equipment like bag filters, hoppers, and vertical conveyors.

-

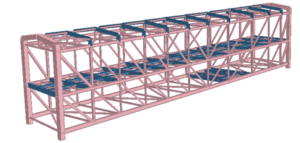

Conveyor Galleries: 32-meter-long steel spans carrying dual conveyors between towers.

-

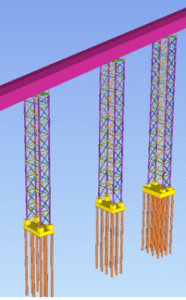

Trestles: Intermediate supports ensuring gallery alignment and structural continuity.

-

Foundations: A hybrid system combining deep pile foundations and raft slabs to resist seismic forces, uplift, and dynamic loads.

The primary structural framework utilized fabricated box sections for columns and standard steel profiles for beams and bracing, optimized for torsional rigidity and load efficiency.

Snaps from Model

Engineering Challenges

-

Wind Loads: High exposure due to tower height and open terrain.

-

Seismic Effects: Located in a high seismic zone, requiring robust lateral load resistance.

-

Dynamic Loads: Continuous conveyor operation imposed vibration and fatigue stresses.

-

Thermal Expansion: Long galleries required movement accommodation.

-

Elevation Coordination: Precise level matching at conveyor interfaces was essential for uninterrupted material flow.

(3D models of transfer tower and conveyor gallery from design software)

Design & Detailing Strategy

1) Structural System

-

Transfer Towers: Designed as braced frames with X-bracing for lateral stability.

-

Conveyor Galleries: Engineered as truss systems to achieve long spans with minimal deflection and vibration.

2) Connection Engineering

-

Pinned-Sliding Joints:

-

One end of each gallery was pinned to transfer vertical and lateral loads.

-

The opposite end featured sliding joints with bearing plates and guide assemblies to accommodate thermal expansion and dynamic movement.

-

-

Welded Brackets to Tower Columns:

-

Custom steel brackets were welded directly to transfer tower columns to receive gallery support.

-

These brackets ensured direct load transfer and simplified erection.

-

3) Foundation System

-

Pile Foundations:

-

Deep cylindrical piles anchored the towers and trestles, resisting uplift and seismic base shear.

-

They were appropriately used in areas with heavy vertical loads and limited space.

-

-

Raft Foundations:

-

Reinforced raft slabs were also used at places where space restrictions were not stringent.

-

4) Platform Design & Equipment Integration

To ensure seamless installation and operation of vendor-supplied machinery, platform structures were designed with critical dimensional accuracy and layout precision:

-

Anchor Point Coordination:

-

Platform beams and base plates were dimensioned to match vendor anchor bolt patterns and machinery footprints.

-

BIM models included embedded plate details and bolt layouts for fabrication and site verification.

-

-

Access & Clearance Zones:

-

Layouts incorporated service access zones, maintenance walkways, and safety buffers around machinery.

-

Clearances were validated in BIM to avoid clashes with structural members, handrails, and adjacent equipment.

-

-

Elevation Matching:

-

Platform heights were precisely aligned with conveyor discharge points and hopper inlets to ensure smooth material transfer.

-

Level control was maintained within tight tolerances to prevent vibration, misalignment, or flow disruption.

-

-

Load Distribution:

-

Structural framing beneath platforms was designed to support concentrated equipment loads, with reinforcement at critical bearing points.

-

Load paths were optimized to transfer forces efficiently into the foundation system.

-

5) BIM Precision: Inclination & Elevation Coordination

-

Conveyor galleries were modeled with exact slope geometry to support gravity-assisted material flow.

-

Inclination was coordinated with mechanical discharge points and process equipment, ensuring optimal alignment.

Project Outcomes

-

Transfer Towers: Achieved stability under wind and seismic loads with optimized bracing and welded bracket interfaces.

-

Conveyor Galleries: Lightweight trusses minimized vibration and allowed controlled movement.

-

Connections: Pinned-sliding joints and bracketed supports ensured safe load transfer and flexibility.

-

Foundations: Hybrid pile-raft system provided tailored resistance across varying load zones.

-

BIM Precision: Enabled flawless elevation matching, slope control, and fabrication-ready detailing.

-

Operational Efficiency: Seamless material flow and equipment integration across the entire system.

Summary

This project exemplifies how precision engineering, intelligent connection detailing, and BIM-driven coordination can transform complex industrial infrastructure into a resilient, efficient, and future-ready system. From seismic-resistant towers to elevation-harmonized conveyor transitions, every element was designed to perform under pressure — and built to last.

About Author

Shana Iqbal is an experienced structural engineer with 6+ years of experience in structural design, analysis, and management of diverse structural projects. Skilled in applying engineering principles to ensure safety, functionality, and cost-effectiveness, she has worked on apartments, refinery, and power plant structures, with a strong focus on innovative and sustainable design solutions. With expertise in structural analysis software, construction practices, and project coordination, she brings both technical knowledge and practical insight to every project.