Introduction

The transformer foundation is more than a simple concrete block; it is a critical structural system that ensures stability, safety, and functionality. It must accommodate extreme static loads, dynamic forces, and environmental hazards, while integrating multiple functional elements such as oil containment pits, cable trenches, mounting rails, pedestals, and firewalls.

This blog explores the complete journey—from physical modeling and load assessment to structural analysis, design, and detailing—of a transformer foundation engineered to meet stringent performance criteria.

Project Overview

Structure Type:

Reinforced concrete transformer foundation system

Design Scope:

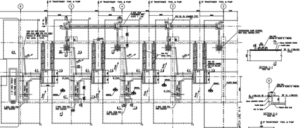

Loading: Dead loads, seismic forces, vibration/dynamic loads, impact during rail operations, and fluid loads (oil and water).

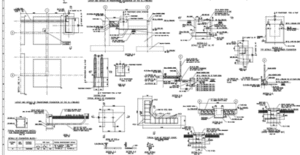

Structural Detailing: Reinforced concrete block with ductile reinforcement and anchorage systems.

Functional Integration: Burnt oil pits for fire safety, cable trenches for routing, vibration isolation pads, and fire-resistant materials.

Primary Challenge

The primary challenge was designing a foundation capable of safely supporting extremely heavy transformer loads while accommodating seismic forces, vibration, and integrating multiple functional elements—such as oil containment, cable trenches, and rails—without compromising structural integrity or serviceability.

Design Challenges

Seismic Vulnerability

In earthquake-prone regions, transformers generate large inertial forces due to their heavy mass. The foundation must be detailed with ductile reinforcement and strong anchorage to prevent displacement and brittle failure during seismic events.

Heavy Concentrated Loads

Transformers impose massive point loads through pedestals or rails, which can overstress soil and concrete locally. The challenge is to distribute these loads evenly using raft or pile foundations while keeping settlements within safe limits.

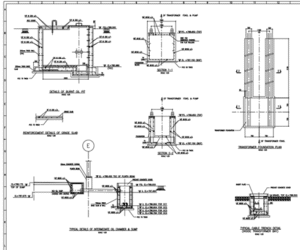

Burnt Oil Pit Integration

Burnt oil pits are essential for fire safety but must be integrated without weakening the structural system. The design ensures adequate capacity, fire-resistant lining, and drainage while maintaining foundation strength.

Cable Trenches

Cable trenches cut through or around the foundation, creating potential weak points. These openings require careful reinforcement to prevent cracking while ensuring waterproofing, fireproofing, and safe cable routing.

Vibration Control

Transformers generate operational vibrations that can affect performance and cause structural fatigue. The foundation must be stiff enough to avoid resonance and include isolation pads to dampen vibrations.

Eccentric Mass Distribution

Despite a nearly rectangular load footprint, eccentric transformer mass requires two-way reinforcement and ductile anchorage to safely resist biaxial bending.

Engineering Strategy & Structural Design

Foundation System:

Reinforced concrete block foundation, raft, or pile-supported system depending on soil conditions.

Seismic Detailing:

Ductile reinforcement, anchorage bolts, and shear keys designed to resist seismic actions.

Burnt Oil Pit:

Designed adjacent to or beneath the foundation, lined with fire-resistant concrete and connected to drainage systems.

Cable Trenches:

Integrated within the foundation layout using reinforced openings to maintain strength and safety.

Vibration Isolation:

Isolation pads provided beneath the transformer to dampen operational vibrations.

Durability Measures:

Fire-resistant concrete mixes, protective coatings, and effective drainage provisions.

Design Outcome Summary

The foundation ensures stability against seismic forces and operational vibrations through robust anchorage and optimized load paths.

Rails and pedestals were aligned to millimeter-level tolerances, ensuring smooth transformer movement and precise equipment positioning.

Controlled deflections, vibration isolation, and crack-width management ensure long-term durability and operational reliability.

Burnt oil pits were successfully integrated for fire safety and environmental protection.

Modular detailing, clear access paths, and removable trench covers simplify installation and future maintenance, reducing downtime and cost.

Summary

Designing transformer foundations requires a multidisciplinary approach. By addressing seismic forces, concentrated loads, vibration control, and the integration of burnt oil pits and cable trenches, engineers create foundations that are not only structurally sound but also functionally safe and operationally reliable.

In critical facilities such as oil and gas plants and power stations, this approach ensures uninterrupted power supply and long-term protection of vital infrastructure. Ultimately, it is clarity in design, precision in detailing, and strong interdisciplinary coordination that transform a simple block of concrete into a high-reliability foundation.

About Author

Jaya P S is an experienced Structural Engineer with 18+ years of hands-on experience in the design and analysis of complex steel structures, including towers, industrial facilities, and transmission infrastructure. Backed by decades of field and software expertise, the insights shared here reflect practical knowledge sharpened through real-world project execution.

Our experts offer full-cycle consulting—from finite element modeling and code compliance to custom foundation detailing.